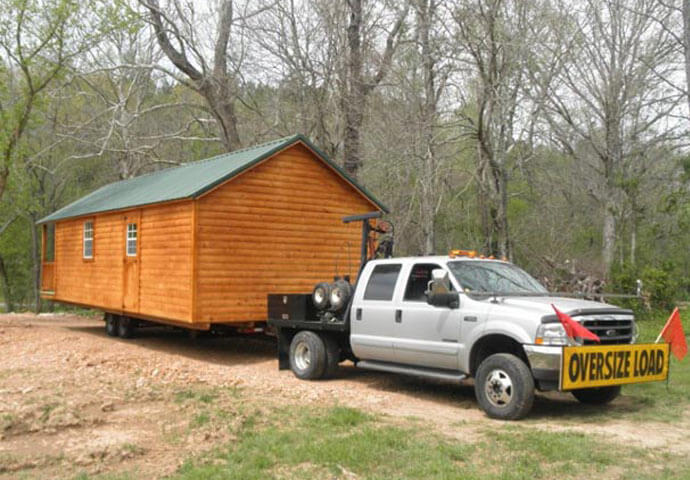

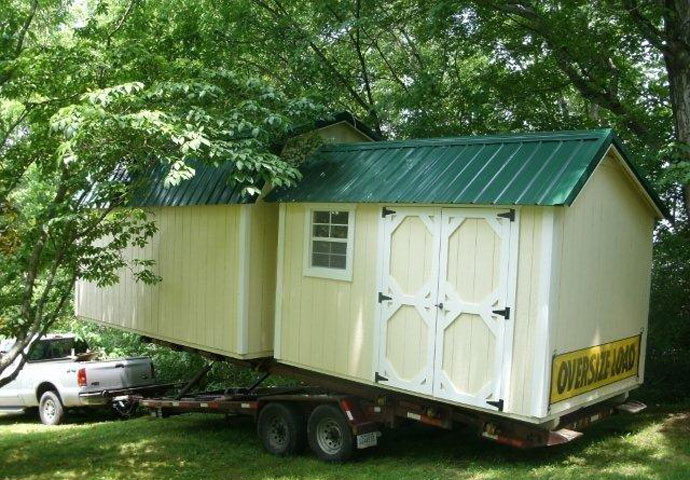

Delivery & Setup

We can deliver and set up your new building on your prepared site.

Don’t worry about setting up your new building in your yard if you have landscaping, a sprinkler system or manicured lawn. Our mobile transport unit (aka “The Mule”) easily moves your new building across your yard without damaging your lawn or equipment!

Our Secretary is here to assist you with any questions about the buildings or to fill out paperwork for an order or give you a free quote on your building.

Download Delivery & Setup Information

Choose a building below to download delivery and setup information.